Pratley Special Acoustic Design Features

General Specs & Design Features

- Optimised SCARF JOINT HEAD ANGLE to provide a good string break angle and superior strength

- High performance NECK CARVE with 2-way adjustable truss rod & twin torsion bars. Both Truss rod & torsion bars run across the 14th fret body intersection which prevents any hump forming.

- Having the truss rod & bars run the full length of the neck allows for a more even relief arc from 1st to last fret.

- FRETBOARD WOODS - are Johnstone River Teak or Wenge. Johnstone River Teak (JRT) is a topical hardwood similar Indian rosewood in density & oil content. It makes a very stable fretboard that sits perfectly in the sweet spot of oily, hard & with a good weight. It also holds frets very well. Wenge is an African wood that is beautiful and dark. It is tonally & visually amazing. This super hardwearing tone-wood is a great addition to our more expensive models.

- NECK POCKET – We use a set neck joining method which means the full thickness neck is glued into a solid timber pocket. The natural taper of the neck when fitted into the pocket creates a wedge joint similar to a horizontal dovetail. We have also eliminated the 'OLD WORLD' heel which came from the Spanish heel method of construction. Removing the heel has reduced weight and allowed greater access to fretboard. Each neck is carefully fitted and glued into the body pocket to maximise resonant transfer.

- FLOATING FRETBOARD – The end of our fretboard sits just above the soundboard. Many companies compromise the soundboard geometry to create the correct angle to glue on the fretboard…. Others machine the fretboard thin to thick to create the angle. We keep the full thickness of our neck & fretboard through, past the last fret and then allow the fretboard to float above the top. Traditional stringed instruments (violin, cello) also do this as it allows the maker to focus on the voice of the soundboard without compromise.

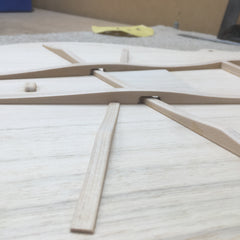

- ACOUSTIC BODY CONSTRUCTION – We use premium Australian tone-woods for our body’s. Our backs have a 4.5M radius dome with premium quarter sawn bunya braces. Our sides are joined to the top and back with our proprietary laser kerf linings. These linings give a greater gluing surface area for the same width. This improves resonant transfer between the top, sides & back. TOP BRACES are also made from premium quarter sawn Bunya. We have designed the Pratley Dipole bracing pattern to prevent bridge roll (top belly-ing) while enhancing the articulation and sweetness of our tone. (started 2015)

- We use traditional Nitrocellulose Lacquer on our acoustic guitars. After years of extensive testing we have concluded that other thicker finishes can reduce the sustain and note complexity.

- We choose to use LR Baggs pickups & pre-amps to faithfully amplify our acoustic voice.